Steel Fabrication

Prior to starting any step with constructing a project, a business must make an effective strategy in the fabrication stage. For many firms like SABS, this is the stage where profits or losses are made. Steel fabrication is the process which involves the conversion of raw material into a finished product which is then going to be used in the construction of steel structures. Steel fabrication differs in many ways due to the many kinds of structured steel. Any Industrial facility uses in order to create anything that benefits their scope of work. At the fabrication stage, we aim to tailor every piece of metal and shape it into the needs of the clients, This is to satisfy the end user to the maximum. In our process, the fabrication proceeds according with shop details and bill of material where each component is a part number which is referenced to the installation drawings.

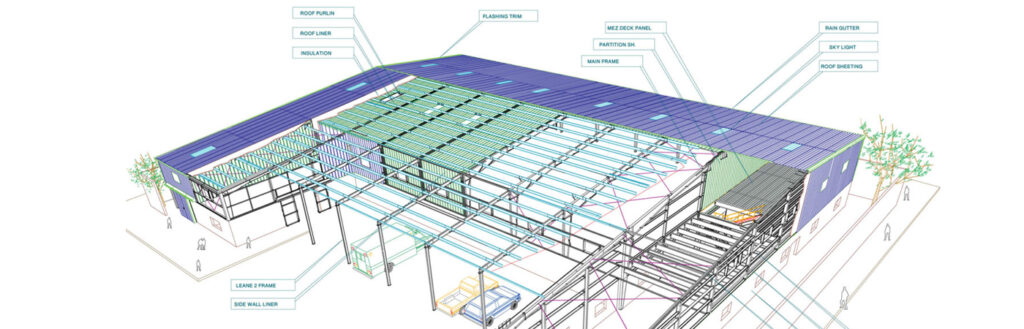

When signing a contract and making the cost estimation, SABS begins to purchase the raw materials required for the certain project. Within a matter of days the raw material is brought to the facility. Furthermore, this is when the fabrication at the facility starts. Our basic stages of fabrication consists of cutting, machining, welding, painting and quality control. First of all, the raw material usually comes in strips, coils or other shapes depending on the supplier. The cutting stage is where we transform the raw material and cut the metal according to the shop details and design of the project. pre engineered buildings mainly consists of either built up sections and hot roll sections. After cutting the steel into the desired shape and steel component, the other stage comes which is machining. This is where cold formed components such as ‘C’ or ‘Z’ shaped structural members are formed. They then become known as roof purlins, eave struts or wall grits. Machines are also used to form roof and wall panels. There are types such as single skin or sandwich panels. At this stage machines are used to tailor the roofing panels according to the type of project and the client. After that, the steel can be welded, which is used to bend or combine pieces of metal to form a certain shape. When that stage is over, the steel is then painted with a layer or two, mainly to prevent the steel from rusting. I also makes the appearance of the steel good to satisfy the client. Finally, before the project is set for shipment or installation, the quality control checks every detail to ensure that there are no faults and everything goes as planned.

The steel fabrication stage is vital for any business. Hence, it decides whether a business can be profitable or lose from a certain project. There must be time efficiency in order to maximize the profits from quality of PEB buildings. Also, trying to minimize the cost of raw materials will benefit the company giving a more breathing space for any errors made during the fabrication process. Another vital benefit in the steel fabrication process is the flexibility in construction. Utilizing the facilities in a factory, steel is a metallurgical property that enables it to be fabricated into any shape and size with ease. Steel structures are fabricated by welding or bolting them together. Structural steel frames are such that an engineer can incorporate last minute changes in the structure and there won’t be an issue. Recyclability also plays a major role in steel fabrication. Cutting, welding and fitting produces waste at any factory, which can then be recycled and used in various other projects. A good metal fabricating company adheres to all the industrial standards and certifications required. They make sure that the tools used by their fabricators are of high quality. With the hard work of the quality control team, SABS ensures that every part of steel that is fabricated is of the highest standard that would always satisfy the end user.